The building industry is constantly seeking optimized solutions to meet the demands of a growing population. One area where significant progress has been made is in the production of Autoclaved Aerated Concrete (AAC). High-quality AAC block production lines utilize cutting-edge technology to manufacture blocks that are lightweight, durable, and energy-efficient. These systems frequently incorporate automated functions to improve production speed, accuracy, and stability.

Some key features found in high-performance AAC block production lines include: sophisticated mixing systems for precise ingredient proportions, automated curing chambers for optimal strength development, and effective cutting and shaping units. By combining these technologies, manufacturers can produce AAC blocks that meet the strictest industry requirements.

Transforming Construction with Automated AAC Machinery

The construction industry is rapidly evolving with the integration of advanced technologies. Among these innovations, automated Autoclaved Aerated Concrete (AAC) machinery stands out as a game-changer, substantially impacting production efficiency and quality. Such machines, equipped with sophisticated controls, automate the entire AAC manufacturing process, from mixing raw materials to cutting and shaping concrete blocks.

This automation provides a multitude of perks. Firstly, it decreases manual labor, enhancing productivity and freeing up workers for more specialized tasks. Secondly, automated AAC machinery operates with high precision, ensuring consistent product quality and reducing waste.

Moreover, these machines employ advanced software algorithms to optimize production parameters, leading in energy efficiency and cost savings. The use of automated AAC machinery is revolutionizing the construction landscape by enabling faster project completion, improved building performance, and a more sustainable approach to construction.

Optimizing AAC Manufacturing Efficiency: Cutting-Edge Technologies

The pressure for greater manufacturing efficiency in the industry of state-of-the-art acoustic communication (AAC) is continuously expanding. Producers are regularly seeking innovative methods to improve production processes and minimize costs. A variety of sophisticated technologies are emerging to address these requirements.

One such technologies is the implementation of artificial intelligence (AI) for process automation. AI-powered systems can analyze vast amounts of data in concurrently to detect inefficiencies and recommend optimizations. This leads to boosted production output and decreased waste.

Another noteworthy technology is the use of rapid prototyping for production of AAC devices. 3D printing offers enhanced design freedom, reduces lead times, and enables the manufacture of intricate geometries that would be challenging to achieve with classic manufacturing methods.

These are just a few instances of how innovative technologies are disrupting AAC manufacturing efficiency.

Sustainable Construction Solutions : AAC Machinery for Eco-Friendly Building

The construction industry is increasingly recognizing the imperative to embrace sustainable practices. Innovative technologies are revolutionizing the way buildings are constructed, minimizing environmental impact while maximizing efficiency. Among these breakthroughs, Autoclaved Aerated Concrete (AAC) machinery stands out as a game-changer for eco-friendly building.

AAC is a lightweight, durable material renowned for its exceptional thermal insulation properties and reduced carbon footprint compared to traditional concrete. Utilizing AAC machinery allows for the automated production of these blocks, streamlining the construction process and reducing waste generation.

The advantages of AAC in sustainable construction are multifaceted:

* Firstly, AAC's lightweight nature reduces the demand for heavy materials and transportation, consequently lowering energy consumption and emissions.

* Moreover, its inherent thermal insulation properties lead to significant energy savings in heating and cooling, contributing to a more environmentally friendly building envelope.

* Thirdly, AAC's production process generates less waste compared to conventional concrete, minimizing the strain on landfills and promoting a circular economy.

Through its effectiveness, AAC machinery empowers builders to create structures that are not only environmentally responsible but also cost-effective and aesthetically pleasing. As the construction industry continues to evolve toward sustainability, AAC is poised to play an increasingly vital role in shaping a greener future.

Pumping in AAC Machinery: Boosting Your Construction Output

AAC machinery represents a strategic investment for Construction AAC Machinery any construction company looking to escalate output and efficiency operations. By utilizing these innovative machines, you can significantly reduce construction timescales while simultaneously improving the quality of your projects.

The inherent flexibility of AAC machinery allows it to excel in a wide range of construction applications, from residential buildings to complex infrastructure projects. Investing in this state-of-the-art technology will not only boost your performance but also place your company as a trailblazer in the industry.

The Future of Construction is Here: Advanced AAC Equipment Innovations

The construction industry is on the brink of a revolution, driven by revolutionary advancements in Autoclaved Aerated Concrete (AAC) equipment. These advanced machines are transforming the way we manufacture structures, offering unprecedented levels of speed and environmental responsibility.

From automated production lines to intelligent control systems, AAC equipment is facilitating builders to create stronger structures with reduced waste.

Furthermore, these innovations are minimizing costs and optimizing the entire construction process.

The future of construction is here, and AAC equipment is leading the way toward a greater sustainable and productive built environment.

Jenna Jameson Then & Now!

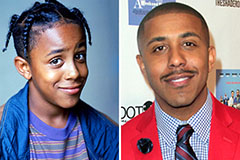

Jenna Jameson Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now!